Since 1978 MB, Mechanics Bordignon – precision mechanics has been operating in the contract-manufacturing sector.

Over the years, we have supplied companies from various areas, earning remarkable experience and high quality levels in many different material types and their treatments.

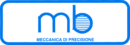

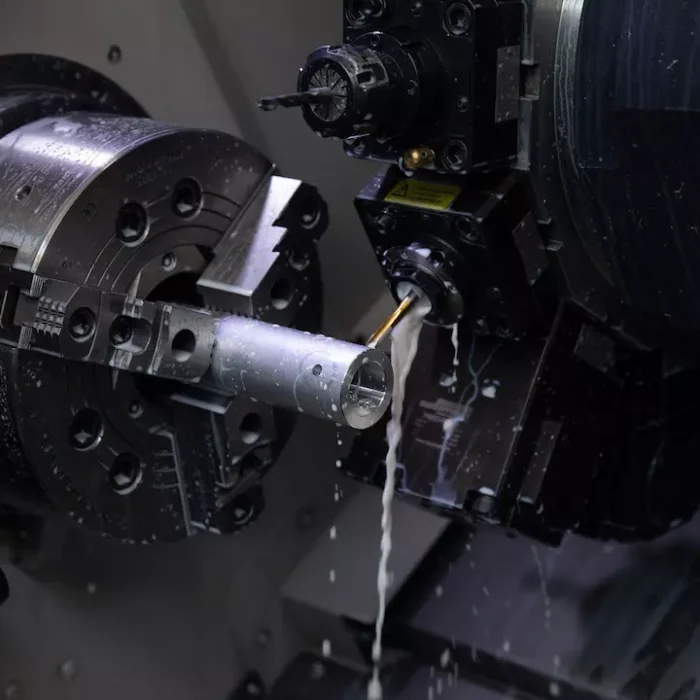

We realize milling, turning and grinding operations on drawings provided by the customer, from the prototype to large series. We also have a cad-cam system, in order to studying and designing details under specific requests.

PROCESSING

Cutting

Milling

Turning

Surface grinding

Testing

Assembly

INTERNAL TREATMENTS

Tumbling

Sandblasting

Total tempering

PROCESSING

Cutting

Milling

Turning

Surface grinding

Testing

Assembly

EXTERNAL TREATMENTS

Cementation

Phosphating

Nickel plating

Nitriding

Induction tempering

Galvanizing

INTERNAL TREATMENTS

Tumbling

Sandblasting

Total tempering

EXTERNAL TREATMENTS

Cementation

Phosphating

Nickel plating

Nitriding

Induction tempering

Galvanizing

INTERNAL TREATMENTS

Tumbling

Sandblasting

Total tempering

EXTERNAL TREATMENTS

Cementation

Phosphating

Nickel plating

Nitriding

Induction tempering

Galvanizing

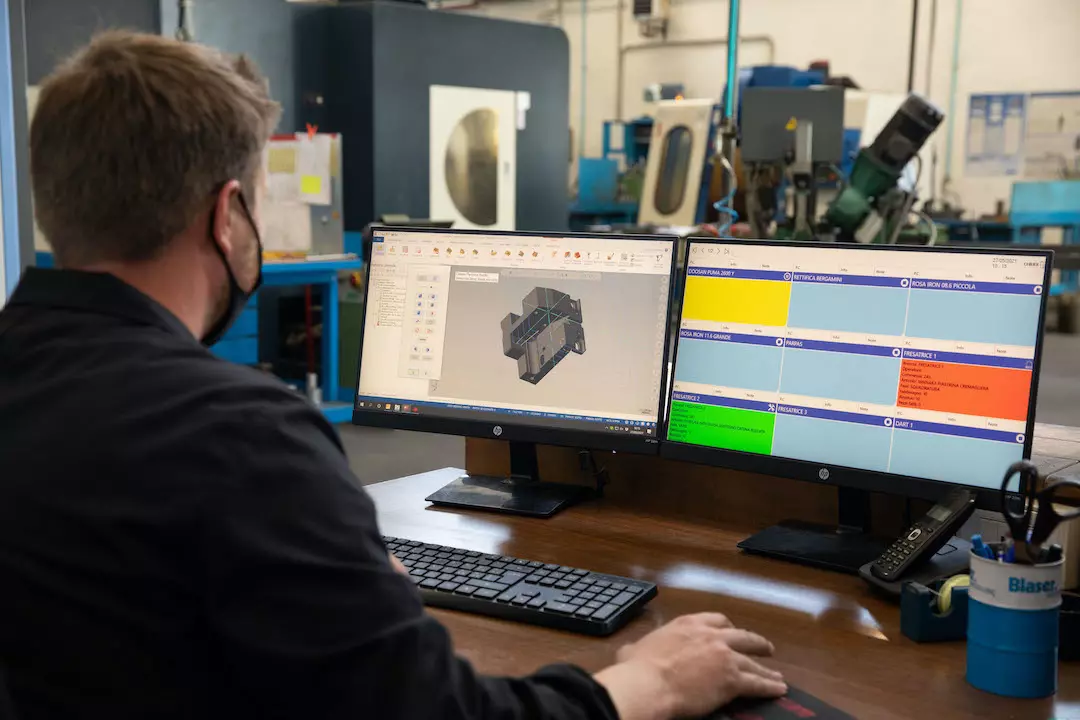

Industry 4.0

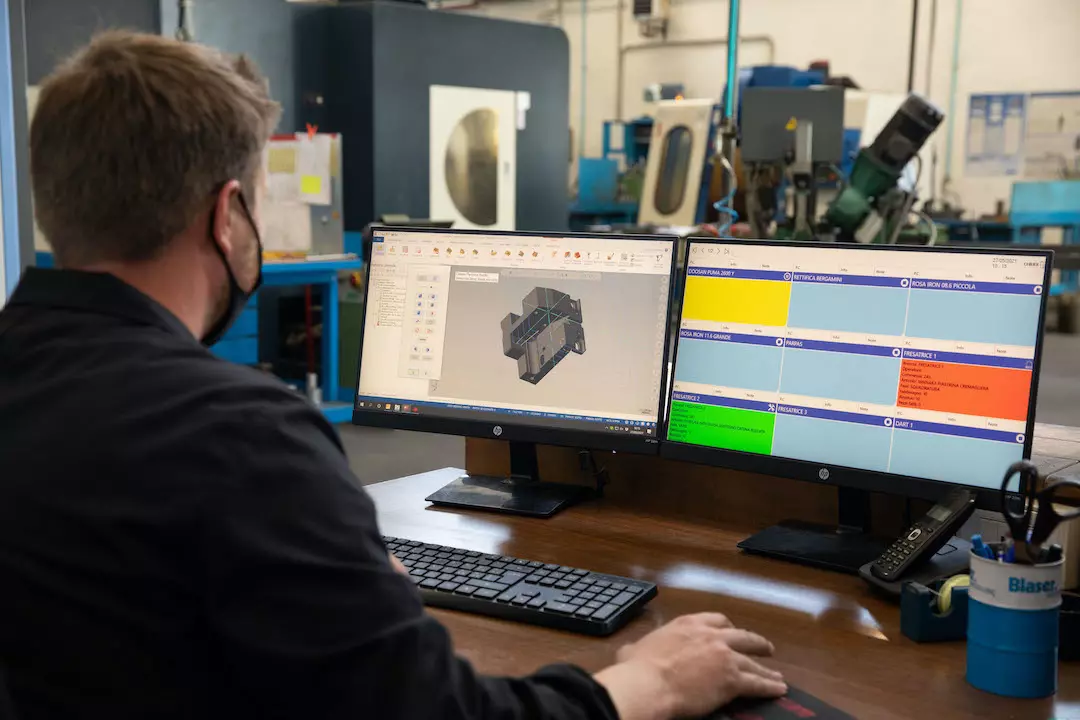

The research of machines, technological tools and the transformation project into industry 4.0 are for our company an ongoing commitment, starting from the introduction of the GP90 management software of O.s.l srl, a must-have element to plan, manage and control all production processes within our company.

The research of machines, technological tools and the transformation project into industry 4.0 are for our company an ongoing commitment, starting from the introduction of the GP90 management software of O.s.l srl, a must-have element to plan, manage and control all production processes within our company.

This particular software allows creating a production cycle worksheet, in which a barcode identifies each single phase and its timing.

Through direct connection with machine operators, who scan the code at the beginning and at the end of each phase, the software is able to provide information in real time to the internal offices and to the customer.

This let us to have an overall vision on orders progress, on state of resources and on materials used.

All this gives to us an additional aid for verification and supervision of the production cycle, improving the quality offered to the customer and the relative satisfaction level.

This particular software allows creating a production cycle worksheet, in which a barcode identifies each single phase and its timing.

Through direct connection with machine operators, who scan the code at the beginning and at the end of each phase, the software is able to provide information in real time to the internal offices and to the customer.

This let us to have an overall vision on orders progress, on state of resources and on materials used.

All this gives to us an additional aid for verification and supervision of the production cycle, improving the quality offered to the customer and the relative satisfaction level.

Please send your request and we will contact you as soon as possible.

Please send your request and we will contact you as soon as possible.